TPO(PVC Free)

PVC Tarpaulin

- Tarpaulin

- Banner & Flex

- Wall Covering

- Roller Blind

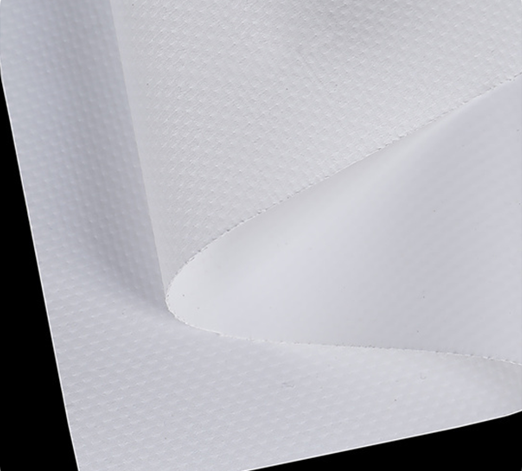

- TPO(PVC Free)

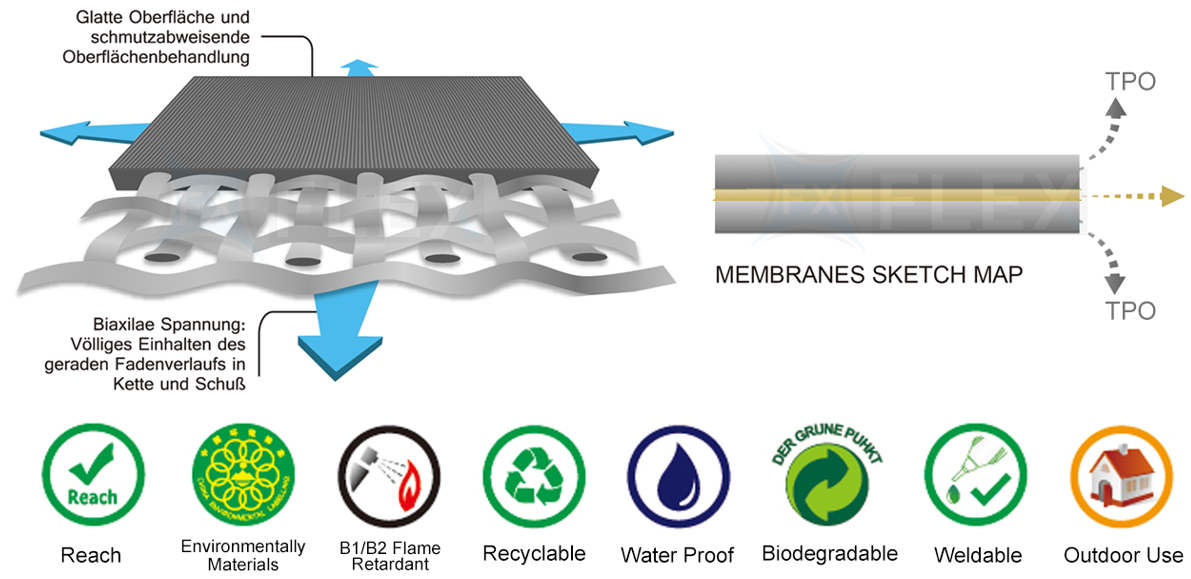

What is TPO?

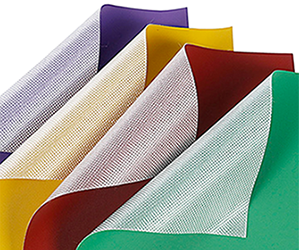

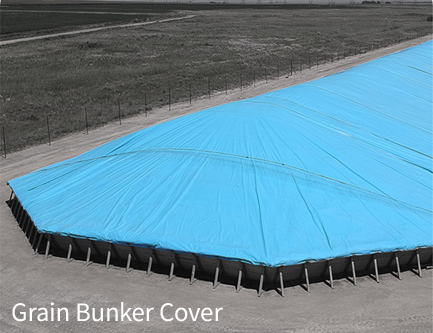

TPO is a new food-grade environmentally friendly formula. It is a polypropylene-based coated fabric with a special thermoplastic polyolefin (TPO) coating formula. This TPO was invented in the United States in the 1990s and is the result of many years of research and development. Introduced to China in 2020, FLFX factory became the first batch of users. TPO fabrics have obvious advantages over existing PVC fabrics. It can be recycled many times to make car fenders, shelves, car mats, etc., and its performance will not decrease; TPO fabric can be 100% degraded within 10 years when buried in the soil, and its environmental performance far exceeds that of PVC fabric.

- 100% Polypropylene-based fabric coated with TPO on both sides

- 100% recyclable, non toxic to humans and no dioxin is emitted when burned Approx. 30% lighter than PVC at the same thickness

- Available from 260 gsm to 800 gsm

- Excellent physical strength-comparable to PVC, including Adhesion strength

- UV-resistant (optional)

- Acrylic lacquer & PVDF treated (optional)

-

Fire-retardant (optional)

- NFPA 701 (large & small scale)

- CPAI 84 sec-6 vertical

- EN13501-1 Class B

- DIN4102 - 126”(3.2m) maximum width for rolls

- 126”(3.2m) maximum width for rolls

TPO Tarpaulin Fabric (PVC Free)

| FLFX10001 | FLFX10002 | FLFX10003 | FLFX10004 | Testing Method | |

|---|---|---|---|---|---|

| Technical properties | |||||

| Total Weight | 400 g/m² 11.8 OZ/YD² | 400 g/m² 11.8 OZ/YD² | 510 g/m² 15 OZ/YD² | 610 g/m² 18 OZ/YD² |

DIN EN ISO 2286-2 BS 3424 Method 5A |

| Base Fabric |

100%PES 500Dtex 9x9/inch |

100%PES 840Dtex 9x9/inch |

100%PES 1000Dtex 18x13/inch |

100%PES 1000Dtex 18x13/inch |

DIN EN ISO 2060 |

|

Tensile Strength (warp/weft) |

800/650 N/5cm 180/150 LBS/2inch |

1280/1040 N/5cm 290/230 LBS/2inch |

2300/1600 N/5cm 520/360 LBS/2inch |

2300/1600 N/5cm 520/360 LBS/2inch |

DIN 53 354 BS 3424 Method FS 5100 |

|

Tear Strength (warp/weft) |

260/210 N 58/47 LBS |

410/340 N 92/76 LBS |

500/350 N 112/78 LBS |

500/350 N 112/78 LBS |

DIN 53 363 BS 3424 Method FS 5134 |

| Adhesion | 60 N/5cm 13 LBS/2inch | 60 N/5cm 13 LBS/2inch | 60 N/5cm 13 LBS/2inch | 60 N/5cm 13 LBS/2inch |

DIN 53 357 FS 5970 BS 3424 Method 9B |

| Width(Optional) | 1.6/ 2.5/ 2.8/ 3/ 3.2/ 5.1m | 1.6/ 2.5/ 2.8/ 3/ 3.2/ 5.1m | 1.6/ 2.5/ 2.8/ 3/ 3.2/ 5.1m | 1.6/ 2.5/ 2.8/ 3/ 3.2/ 5.1m | - |

|

Temperature Resistance |

-40°C / +80°C | -40QC / +80°C | -40cC / +80°C | -40cC / +80°C |

DIN EN 1876-2 BS 3424 Method 10 FS 5874 |

|

Flame Retardancy (Optional) |

B1,B2 | B1,B2 | B1,B2 | B1,B2 |

EN 13501 NFPA-701 ASTM E84 |

|

Lacquering (Optional) |

Acrylic & PVDF | Acrylic & PVDF | Acrylic & PVDF | Acrylic & PVDF | |

| Application | Tarpaulin | Tarpaulin | Tarpaulin | Tarpaulin |

TPO Flex Banner (PVC Free)

| FLFX10005 | FLFX10006 | FLFX10007 | FLFX10008 | Testing Method | |

|---|---|---|---|---|---|

| Technical properties | |||||

| Total Weight | 300 g/m² 8.8 OZ/YD2² | 350 g/m² 10.3 OZ/YD² | 350 g/m² 10.3 OZ/YD² | 400 g/m² 11.8 OZ/YD² |

DIN EN ISO 2286-2 BS 3424 Method 5A |

| Base Fabric |

100%PES 500Dtex 9x9/inch |

100%PES 840Dtex 9*9/inch |

100%PES 1000Dtex 18x13/inch |

100%PES 1000Dtex 18x13/inch |

DIN EN ISO 2060 |

|

Tensile Strength (warp/weft) |

800/650 N/5cm 180/150 LBS/2inch |

1280/1040 N/5cm 290/230 LBS/2inch |

2300/1600 N/5cm 520/360 LBS/2inch |

2300/1600 N/5cm 520/360 LBS/2inch |

DIN 53 354 BS 3424 Method FS 5100 |

|

Tear Strength (warp/weft) |

260/210 N 58/47 LBS |

410/340 N 92/76 LBS |

500/350 N 112/78 LBS |

500/350 N 112/78 LBS |

DIN 53 363 BS 3424 Method FS 5134 |

| Adhesion | 60 N/5cm 13 LBS/2inch | 60 N/5cm 13 LBS/2inch | 60 N/5cm 13 LBS/2inch | 60 N/5cm 13 LBS/2inch |

DIN 53 357 FS 5970 BS 3424 Method 9B |

| Width(Optional) | 1.6/ 2.5/ 2.8/ 3/ 3.2/ 5.1m | 1.6/ 2.5/ 2.8/ 3/ 3.2/ 5.1m | 1.6/ 2.5/ 2.8/ 3/ 3.2/ 5.1m | 1.6/ 2.5/ 2.8/ 3/ 3.2/ 5.1m | - |

|

Temperature Resistance |

-40°C / +80°C | -40QC / +80°C | -40cC / +80°C | -40cC / +80°C |

DIN EN 1876-2 BS 3424 Method 10 FS 5874 |

|

Flame Retardancy (Optional) |

B1,B2 | B1,B2 | B1,B2 | B1,B2 |

EN 13501 NFPA-701 ASTM E84 |

|

Lacquering (Optional) |

Acrylic & PVDF | Acrylic & PVDF | Acrylic & PVDF | Acrylic & PVDF | |

| Application | Banner | Banner | Banner | Banner |

TPO Recycling